DTF Pre Pressing and Why It Matters

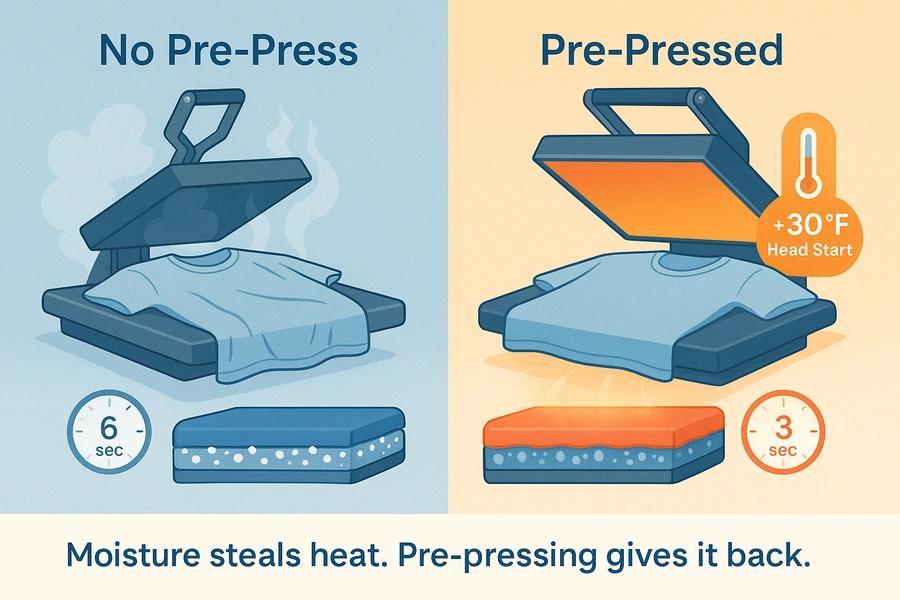

The BIGGEST barrier to fast, consistent adhesion is water. Pre-pressing drives out moisture and adds a small but meaningful thermal boost, making short 3 second press cycles more reliable. If you're running longer dwell times at high temps, you might get away without it—but if you care about color accuracy, hand feel, and repeatable results, pre‑pressing is worth the few extra seconds.

Before You Continue...

We calibrate our DTF printing process—including ink, adhesive, and press settings—for short dwell times at lower temperatures (typically 3–5 seconds at 280–290 °F). This preserves color fidelity and ensures a soft hand feel.

If you skip the pre‑press step, you’ll need to increase your dwell time—potentially doubling it to ensure full adhesion. That means pressing for 6–10 seconds minimum (but not more than 12). Just keep in mind: longer press times can degrade color and feel, especially on delicate fabrics or high-color designs.

In short: don’t skip the pre‑press unless you’re willing to adjust everything else.

Does Pre‑Pressing Really Help, or Is It Just About Moisture?

Short answer: it’s mostly about removing moisture and air from the garment—but that quick pre‑heat can also help the adhesive hit melt temperature faster, especially when you're running 3–5 second dwell cycles. In short-dwell workflows, every fraction of a second matters.

What Pre‑Pressing Actually Does

Evaporates Moisture

Cotton can hold over 5% water by weight. Every gram takes ~540 cal to boil off, stealing heat from the TPU adhesive and slowing melt.

Flattens Fibers/Seams

A flatter surface ensures even pressure and gives the powder a smooth “landing strip.

Pre‑Heats the Fabric

Raises surface temp by 25–40 °F, giving the TPU a head start on reaching melt-flow.

How Much Does the Pre‑Heat Really Help?

The PET carrier, ink, and adhesive layers are thin—less than 0.1 mm combined—and while they add some thermal resistance, they’re not brick walls. But moisture is the real drag.

A damp shirt can double the time it takes for the transfer surface to climb from 200 °F to 280 °F, because your press first has to boil off water before fusing the adhesive.

That’s why pre‑pressing matters even more in fast workflows. Saving 0.5–1.0 seconds on TPU melt time might not sound like much—until you’re aiming to hit full adhesion in just 3 seconds.

When Pre‑Pressing Really Pays Off

Humid Shop / Cotton Tees

Removes steam that causes cold spots, blisters, or uneven adhesion.

Thick Ink Stacks / Heavy Powder

Stored heat helps overcome the insulating effect of bulky transfers. We calibrate our machines to avoid this, but it is worth mentioning here.

Performance Wear (Poly Blends)

Helps avoid scorching by reducing main press temp; with a heated lower platen, pre‑pressing can activate adhesive from both sides.

Bottom Line

Pre‑pressing isn’t magic—but it does remove the #1 barrier to fast, consistent adhesion: water. And it adds just enough thermal boost to make a 3‑second cycle more reliable.

If you’re running long dwell times at high temps, you might get away without it—but if you care about color, softness, and consistency, a quick pre‑press is time well spent.

What People Are Saying

FIVE STARS!

"With Dmandprints, I’ve increased my business by over 30%, while saving both time and money. Their quality, service, and attention to detail have been outstanding—highly recommended!"

Essential Tips for Quality DTF Printing

Our guides are perfect for both beginners and seasoned print professionals. Discover valuable tips for creating artwork, mastering heat press techniques, and more. These resources ensure you achieve the best quality final product.

What Makes Dmandprints Different

Loading...

Popular Guides

Loading...

Creating Images for DTFs

Loading...

Feature Articles

Loading...

Q & A

Common Questions

Here are some quick questions and answers we frequently get about DTF prints and DMandPrints. We've placed them right here on the home page for your convenience!

Do you really think you have the best prints in the world?!

Do you really think you have the best prints in the world?!

Mmm... we think they’re pretty great—and we work relentlessly to keep making them better. It’s a bold claim (maybe even a little cocky), so we’ll let the results speak for themselves.

Do you sell printed garments?

Do you sell printed garments?

No, we only sell the prints.

You can purchase your own garment and a heat press to apply the heat transfer prints to your own garments. Our customers are typically small, medium and large screen printers that want to offer heat transfers as an alternative to their standard screen printing process.

Is Gang Sheeting Necessary for Your Artwork?

Is Gang Sheeting Necessary for Your Artwork?

There is no need to gang sheet your artwork.

We charge only for the actual print area. Our image processing system automatically removes any unnecessary transparent space around your image to accurately calculate the print area for our per-square-inch pricing.

Gang sheeting not only costs you time but can also cost you money. We can only trim transparent space around the edges of your artwork. If you create a gang sheet yourself, you might introduce unprinted space that increases the total square inches, leading to higher costs.

Summary

The easiest and most cost-effective way to get your prints is to simply upload your artwork. We'll handle the gang sheeting for you, saving you both time and money.

Are DTF prints better than traditional screen printing?

Are DTF prints better than traditional screen printing?

It's not a matter of being better or worse; DTF (Direct to Film) printing is simply an alternative to traditional screen printing. Both methods have their own unique advantages.

DTF heat transfers feel similar to screen-printed shirts and can often be more durable. Additionally, DTF printing allows for unlimited colors in a single print, providing flexibility for intricate and colorful designs. On the other hand, screen printing is well-loved for its ability to produce vibrant, long-lasting prints, especially in bulk.

Choosing between the two methods depends on your specific needs and preferences.

What types of fabrics can DTF prints be applied to?

What types of fabrics can DTF prints be applied to?

DTF prints can be applied to a variety of fabrics, including cotton, polyester, blends, leather, and even some non-textile materials.

Are DTF prints durable?

Are DTF prints durable?

Yes, DTF prints are known for their durability and can withstand multiple washes without fading or peeling.

Do DTF prints feel heavy or stiff?

Do DTF prints feel heavy or stiff?

No, DTF prints have a soft feel and do not add significant weight or stiffness to the fabric.

Can DTF prints be used for detailed and colorful designs?

Can DTF prints be used for detailed and colorful designs?

Yes, DTF prints are excellent for detailed and colorful designs, providing vibrant and high-resolution results.

Is DTF printing cost-effective for small batches?

Is DTF printing cost-effective for small batches?

Yes, DTF printing is cost-effective for both small and large batches, making it ideal for custom and limited-run designs.

Can I create DTF prints at home?

Can I create DTF prints at home?

While it's possible with the right equipment, most people prefer to use professional services for higher quality and ease of use.