DTF Heat Transfer Powder: Why Some Transfers are Better Than Others

Your heat transfers might look good at first glance—but do your customers keep coming back? If your prints feel stiff, peel after a few washes, or simply don't hold their color, your DTF adhesive powder might be to blame. Surprisingly, something as simple as the powder used in your prints could be making or breaking your customer retention and business reputation. Here’s why it matters, and what you absolutely need to know…

The Cheat Sheet

Pressed for Time? Here’s the Headline:

- Low-quality prints can slowly destroy your apparel business.

- The biggest culprit is often cheap, low-grade TPU powder.

- Many large, discount DTF print providers use inferior powder to cut costs.

- There's one simple giveaway that your provider is compromising on quality:

If their pressing instructions require temperatures above 290°F and press times longer than 5 seconds, they're likely using cheap powder. - If you are printing your own transfers and struggling to improve the look and feel of your prints, check the TPU powder you are using.

- The result?

Transfers that look dull, feel stiff and plastic-like, crack and peel after washes, and ultimately drive your customers away. - Low quality TPU powder is less healthy

Pure, high-grade TPU powders minimize harmful volatile organic compounds (VOCs), fumes, and particulate matter. This is important for the printer, the presser and the person wearing the final product.

Demonstration of why this matters

Before you continue, check out this simple demonstration showing why time and temperature matter in the final result. Note that we used high-quality adhesive powder for all test prints—if we had used low-quality powder, the higher time and temperature settings would have caused even more noticeable changes in color and feel.

What Is DTF Adhesive Powder

DTF Adhesive powder is what bonds the print to your fabric. The quality of the adhesive powder has a MASSIVE impact on the quality of the feel. It also directly impacts the colors because low quality powder requires longer and hotter press times which not only burn fabric but can also change the actual color of the ink on the print.

Let's Get Nerdy: Introduction to Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU) is a category of polyurethane plastics valued for their elasticity, durability, clarity, and abrasion resistance. Structurally, TPU is a segmented block copolymer consisting of alternating soft segments (providing elasticity) and hard segments (contributing mechanical strength and thermal stability). This composition imparts TPU with a unique balance of flexibility, strength, and thermal characteristics, making it an ideal adhesive powder for Direct-to-Film (DTF) printing.

Why TPU is Ideal for DTF Printing

TPU serves as a crucial component in DTF transfers, functioning as the bonding layer between the printed ink and fabric substrate. Several inherent attributes make TPU particularly well-suited to this task:

Soft Hand Feel

Premium TPU produces transfers that are comfortable, soft, and non-plastic in feel, crucial for garments worn directly against the skin.

Flexibility and Stretch

High-quality TPU ensures transfers flex and stretch naturally with fabrics, preventing cracking or peeling during normal use.

Strong Fabric Adhesion

TPU bonds effectively to various fabrics, including cotton, polyester, and blends, enhancing durability and lifespan.

Wash Durability

High-grade TPU maintains adhesion and visual quality after multiple washes, resisting degradation over time.

Key Quality Indicators of TPU in DTF Transfers

The quality and performance of TPU powders are defined by several measurable and controllable factors. These critical attributes help distinguish premium TPU powders from lower-quality alternatives:

Melt Flow Index (MFI)

The Melt Flow Index measures the ease and rate of flow of a thermoplastic polymer when melted, expressed in grams per 10 minutes under standardized testing conditions (ASTM D1238).

High MFI TPU (Ideal)

- Provides quick, even melting and improved penetration into fabric fibers.

- Facilitates lower press temperatures (280–290°F) and shorter pressing times (approximately 3 seconds).

- Results in softer, more comfortable transfers.

Low MFI TPU (Inferior)

- Requires higher temperatures (290–320°F) and longer pressing (12–15 seconds).

- Produces stiff, uncomfortable transfers due to prolonged heat exposure.

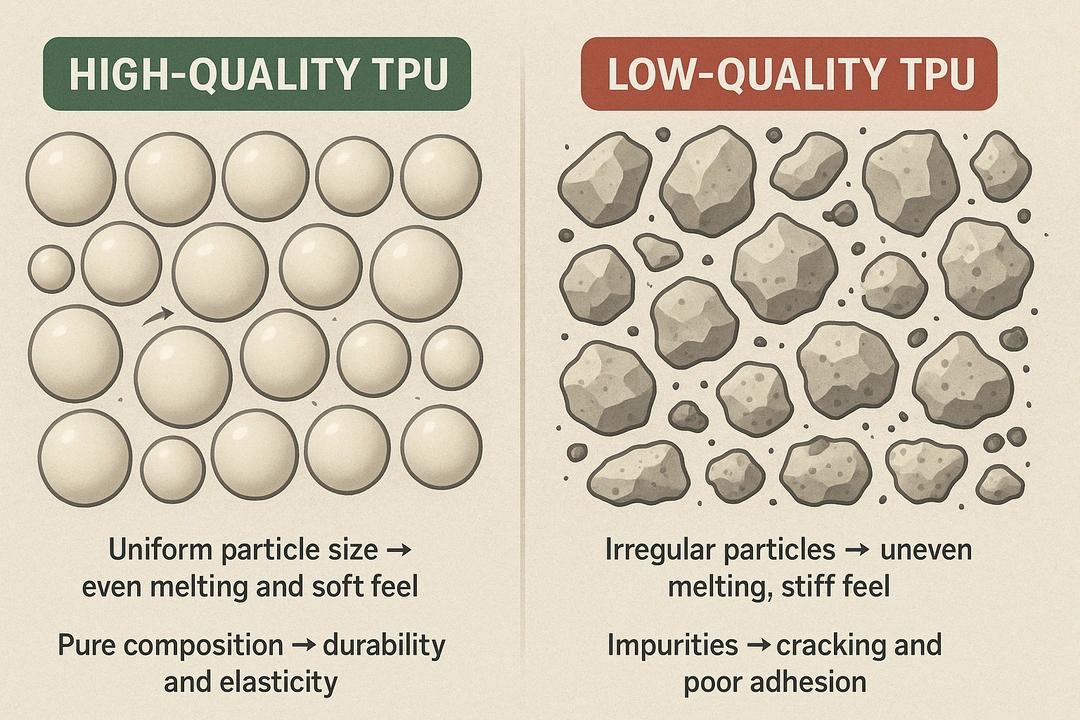

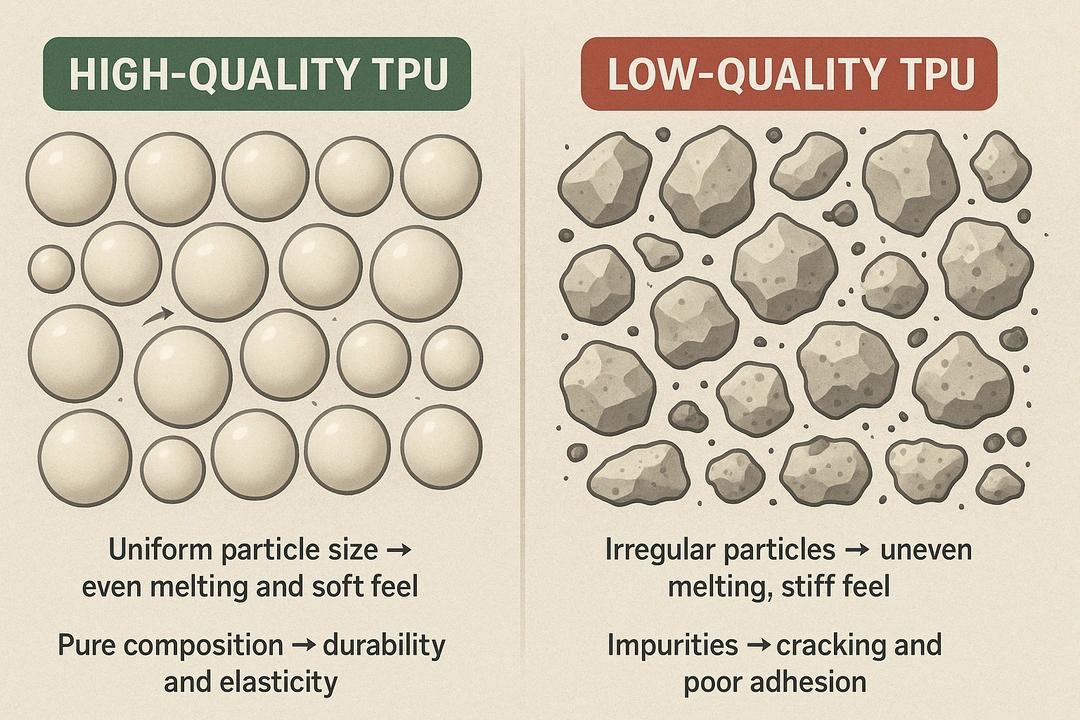

Particle Size and Distribution

Uniform particle size and narrow distribution significantly affect TPU powder performance. High-quality powders feature:

- Even melting and smooth coatings.

- Consistent adhesion and enhanced durability.

Inferior powders with inconsistent particle sizes produce uneven, rough-textured, and unreliable adhesion, requiring excessive heating and pressing.

Thermal Stability and Predictability

Premium TPU powders exhibit consistent melting behavior within a tight temperature range, allowing precise processing control and optimal fabric compatibility. In contrast, lower-quality powders demonstrate broad, unstable melting ranges, necessitating harsh pressing conditions to ensure adhesion at the expense of softness and fabric integrity.

Chemical Purity and Composition

High-quality TPUs are formulated from pure polyols and isocyanates without fillers or contaminants. This purity directly influences:

- Improved elasticity and softness.

- Enhanced visual vibrancy and color stability.

- Increased wash resistance and long-term performance.

Inferior TPUs containing contaminants or fillers lead to brittleness, color degradation, reduced durability, and potential health risks.

Elasticity and Recovery

Premium TPU maintains elasticity, allowing garments to flex and recover their shape after stretching. Inferior TPU results in brittle, rigid transfers prone to cracking and peeling.

Why Lower-Quality TPU Powders Are Commonly Used

Many large-scale DTF providers rely on cheaper, inferior TPU powders primarily to reduce costs and simplify production. They often resort to elevated pressing temperatures (290–320°F) and extended press times (12–15 seconds) as a brute-force strategy to guarantee adhesion. The trade-off is significantly compromised comfort, flexibility, color vibrancy, and increased risk of garment damage.

The Economics of High-Quality TPU

Premium TPU powders inherently cost more due to tangible differences in materials and processes, not simply marketing:

Superior Raw Materials

High purity and absence of fillers result in better performance but higher costs.

Complex Manufacturing

Precise chemical synthesis, advanced powder milling, and controlled particle size distribution require expensive processes and equipment.

Rigorous Quality Control

Extensive testing (MFI, particle size, thermal stability, elasticity) ensures consistent batch-to-batch quality, adding operational costs.

R&D and Innovation

Continuous formulation enhancements and production innovations require significant ongoing investment.

Environmental Compliance

High-end TPUs adhere to stringent environmental and safety regulations, further increasing costs.

Specialized Production Scale

Smaller, specialized production batches reduce economies of scale, leading to higher per-unit costs.

These factors justify the premium pricing of high-quality TPU, delivering tangible value and superior transfer performance.

Safety and Health Benefits of High-Quality TPU

Higher-quality TPU powders offer enhanced safety across several dimensions:

Operator Safety (Printing and Pressing)

Pure, high-grade TPU powders minimize harmful volatile organic compounds (VOCs), fumes, and particulate matter. This results in safer working conditions during powder application, curing, and heat pressing.

Consumer Safety (Garment Wear)

Premium TPU ensures the absence of harmful contaminants, plasticizers, heavy metals, and other toxic chemicals, significantly reducing skin irritation and allergic reactions, and complying with international textile safety standards (e.g., OEKO-TEX, REACH compliance).

Conversely, lower-quality powders may contain hazardous additives or contaminants, potentially exposing operators and consumers to health risks.

Empirical Data from The Printers, TPU, and Inks We Use

Our practical experience using industrial-grade printers, Dupont Artistry inks, and optimized TPU powder has consistently demonstrated performance that is indicative of high quality TPU powder.

Lower Temperature and Reduced Press Time

Achieved reliable adhesion at 280–290°F for only 3 seconds, significantly lower than industry averages.

Superior Feel and Flexibility

Transfers consistently exhibit exceptional softness, elasticity, and comfort.

Outstanding Durability and Color Stability

Empirical testing shows excellent wash resistance and vibrant, accurate colors over time.

This empirical evidence strongly indicates the premium nature of the TPU adhesive powder, with optimized attributes such as ideal MFI, particle uniformity, and chemical purity.

Summary before we get super nerdy!

In summary, the superior performance of high-quality TPU powder in DTF applications directly correlates to its advanced manufacturing processes, rigorous quality controls, chemical purity, optimal MFI, consistent particle sizing, and robust safety profile.

While high-quality TPU adhesive powders are inherently more expensive due to these stringent controls and premium raw materials, their benefits clearly justify this cost—providing durable, comfortable, visually superior, and safer transfers. These attributes distinctly set apart DTF prints produced using premium industrial-grade TPU powder, such as those utilized by Cobraflex printers and Dupont Artistry inks, from the widespread industry-standard alternatives.

We use the CobraFlex PU75 Powder and here's why

First, our entire fleet is CobraFlex—period. One of the biggest reasons is that if you think we’re nerdy about this stuff, we’re nothing compared to the experts at CobraFlex. Their depth of knowledge is unmatched, and they share our obsessive commitment to quality.

The Super Nerdy Cheat Sheet on CobraFlex PU75

It ain’t cheap—because it’s not cheap.

PU75 is a premium-grade Thermoplastic Polyurethane (TPU), purpose-built for comfort, durability, and predictable performance.

- High Purity (>99.9%)

Virtually contaminant-free, delivering superior softness, stretch, and vibrant color payoff. - Thermoplastic TPU Structure

Allows clean, consistent melting and pressing at lower temps (280–290°F), making your workflow smoother. - Narrow Melting Range (110–120°C)

Enables precise process control for a better hand feel and reliable adhesion. - Excellent Safety Profile

Non-hazardous formulation—safer for operators, pressers, and wearers alike.

PU75 Safety Data Sheet Analysis

Here's a detailed analysis based on the Safety Data Sheet (SDS) from CobraFlex, along with addressing important questions regarding the terminology (PU75) and the distinction between PU (Polyurethane) and TPU (Thermoplastic Polyurethane) as used in DTF adhesive powders.

Material Composition:

- Primary Material: Thermoplastic Polyurethane (fully reacted)

- Purity: >99.9% polyurethane polymers, <0.1% stabilizing agents/additives

- Appearance: White to semi-transparent powder

- Melting Range: 110°C – 120°C (230°F – 248°F), indicating a tightly controlled melting range conducive to predictable results and reliable melting behavior at lower press temperatures.

Health and Safety Overview:

- Hazard Classification: Non-hazardous under GHS criteria; not classified as dangerous goods under transport regulations.

- Exposure Controls: Standard personal protective equipment recommended, including gloves, respiratory protection for dust, and eye protection. The powder itself is not hazardous or toxic in normal handling and use scenarios.

- Environmental Considerations: Non-toxic to aquatic life at normal use concentrations; moderate biodegradability. Avoid uncontrolled release into water systems.

- Stability: Chemically stable under recommended storage conditions (below 25°C) with minimal risk of hazardous reactions or decomposition.

Notable Findings:

- Quality Indicators: The high purity (over 99.9%) and a narrow melting point range strongly suggest a high-quality TPU designed for consistent performance in DTF processes.

- Safety Profile: Non-hazardous classification highlights its safety advantages compared to lower-quality powders, which may contain contaminants or hazardous substances.

Clarifying PU vs TPU

The term PU75 refers explicitly to Polyurethane (PU), specifically "Thermoplastic Polyurethane." Let's clarify the terminology and implications:

Polyurethane (PU) vs. Thermoplastic Polyurethane (TPU):

- PU (Polyurethane):

A broad category of polymers containing urethane linkages. Polyurethanes can be either thermoplastic (re-meltable, recyclable) or thermoset (cannot be re-melted after curing). - TPU (Thermoplastic Polyurethane):

A specific subclass of PU that remains thermoplastic after polymerization. TPUs have elastic properties similar to rubber but maintain plastic-like processability (melting, remolding).

PU75 is explicitly described as "Thermoplastic Polyurethane," meaning it is indeed a TPU variant:

- "Thermoplastic" indicates it can be repeatedly melted and reformed without significant chemical degradation.

In other words, the label "PU75" doesn't imply a thermosetting polyurethane (which would not melt or remelt), but rather clearly states it's a thermoplastic variant ideal for adhesive powder applications.

Differences Between PU and TPU in DTF Applications (Why TPU is Preferred):

While TPU is a type of PU, in practice, the distinction matters significantly:

AttributeThermoset PUThermoplastic PU (TPU) (like PU75)Heat ReactivityIrreversible curingRepeatedly meltable (ideal for DTF)Flexibility & ElasticityLower flexibility (after cure)High elasticity and stretch recoveryDurability & Wash ResistanceHigh but less flexibleVery high, flexible durabilityHand Feel & ComfortPotentially stiff/hardSoft, comfortable, fabric-like feelProcessing Temps and TimesOften higher and more variablePredictably lower and shorter

Conclusion:

TPU (like your PU75 powder) offers distinct advantages over general-purpose PU for DTF printing because of its controlled melting behavior, exceptional flexibility, and comfort.

TPU (like your PU75 powder) offers distinct advantages over general-purpose PU for DTF printing because of its controlled melting behavior, exceptional flexibility, and comfort.

Why Do Some Providers Use the Term "PU" Instead of "TPU"?

The terms "PU" and "TPU" can sometimes be used interchangeably, though inaccurately. Typically, companies may label TPU products simply as PU for marketing brevity. However, the SDS explicitly clarifies that your "PU75" powder is indeed thermoplastic polyurethane.

This means your CobraFlex PU75 powder is accurately a high-quality TPU variant, perfectly suited for DTF applications.

Summary of Why PU75 Powder is a High Quality TPU (From SDS Evidence):

- High Purity (>99.9%): Ensures minimal contaminants, providing superior softness, flexibility, and color vibrancy.

- Thermoplastic (TPU) Structure: Enables controlled, repeatable melting and pressing at lower temperatures (280–290°F).

- Narrow Melting Range (110–120°C): Provides precise process control, optimal hand feel, and consistent adhesion.

- Safety Profile: Non-hazardous formulation safer for operators and end-users.

Final Recommendation for Article Clarity:

Given the SDS and our Imperical evidence based on results from the final products we've produced.

- The powder (PU75) is a premium Thermoplastic Polyurethane (TPU) variant, specifically engineered for superior comfort, durability, and processability.

- Lower-quality DTF powders often labeled generically as "PU" may not exhibit true TPU characteristics, explaining their poor hand feel, higher pressing requirements, and lower durability.

- There is a clear distinction in quality and safety benefits between PU and TPU powders that will make or break the quality of the print.

If you’ve made it this far—props to you.

I wrote this mostly for myself, to document exactly why we made the decisions we did about our process, equipment, and workflow. But I also wanted to provide real evidence behind the claims we make about print quality—on our website and our YouTube channel.

Hopefully, this helps anyone buying DTF prints now—or planning to invest in their own printer down the road.

What People Are Saying

FIVE STARS!

"With Dmandprints, I’ve increased my business by over 30%, while saving both time and money. Their quality, service, and attention to detail have been outstanding—highly recommended!"

Essential Tips for Quality DTF Printing

Our guides are perfect for both beginners and seasoned print professionals. Discover valuable tips for creating artwork, mastering heat press techniques, and more. These resources ensure you achieve the best quality final product.

What Makes Dmandprints Different

Loading...

Popular Guides

Loading...

Creating Images for DTFs

Loading...

Feature Articles

Loading...

Q & A

Common Questions

Here are some quick questions and answers we frequently get about DTF prints and DMandPrints. We've placed them right here on the home page for your convenience!

Do you really think you have the best prints in the world?!

Do you really think you have the best prints in the world?!

Mmm... we think they’re pretty great—and we work relentlessly to keep making them better. It’s a bold claim (maybe even a little cocky), so we’ll let the results speak for themselves.

Do you sell printed garments?

Do you sell printed garments?

No, we only sell the prints.

You can purchase your own garment and a heat press to apply the heat transfer prints to your own garments. Our customers are typically small, medium and large screen printers that want to offer heat transfers as an alternative to their standard screen printing process.

Is Gang Sheeting Necessary for Your Artwork?

Is Gang Sheeting Necessary for Your Artwork?

There is no need to gang sheet your artwork.

We charge only for the actual print area. Our image processing system automatically removes any unnecessary transparent space around your image to accurately calculate the print area for our per-square-inch pricing.

Gang sheeting not only costs you time but can also cost you money. We can only trim transparent space around the edges of your artwork. If you create a gang sheet yourself, you might introduce unprinted space that increases the total square inches, leading to higher costs.

Summary

The easiest and most cost-effective way to get your prints is to simply upload your artwork. We'll handle the gang sheeting for you, saving you both time and money.

Are DTF prints better than traditional screen printing?

Are DTF prints better than traditional screen printing?

It's not a matter of being better or worse; DTF (Direct to Film) printing is simply an alternative to traditional screen printing. Both methods have their own unique advantages.

DTF heat transfers feel similar to screen-printed shirts and can often be more durable. Additionally, DTF printing allows for unlimited colors in a single print, providing flexibility for intricate and colorful designs. On the other hand, screen printing is well-loved for its ability to produce vibrant, long-lasting prints, especially in bulk.

Choosing between the two methods depends on your specific needs and preferences.

What types of fabrics can DTF prints be applied to?

What types of fabrics can DTF prints be applied to?

DTF prints can be applied to a variety of fabrics, including cotton, polyester, blends, leather, and even some non-textile materials.

Are DTF prints durable?

Are DTF prints durable?

Yes, DTF prints are known for their durability and can withstand multiple washes without fading or peeling.

Do DTF prints feel heavy or stiff?

Do DTF prints feel heavy or stiff?

No, DTF prints have a soft feel and do not add significant weight or stiffness to the fabric.

Can DTF prints be used for detailed and colorful designs?

Can DTF prints be used for detailed and colorful designs?

Yes, DTF prints are excellent for detailed and colorful designs, providing vibrant and high-resolution results.

Is DTF printing cost-effective for small batches?

Is DTF printing cost-effective for small batches?

Yes, DTF printing is cost-effective for both small and large batches, making it ideal for custom and limited-run designs.

Can I create DTF prints at home?

Can I create DTF prints at home?

While it's possible with the right equipment, most people prefer to use professional services for higher quality and ease of use.